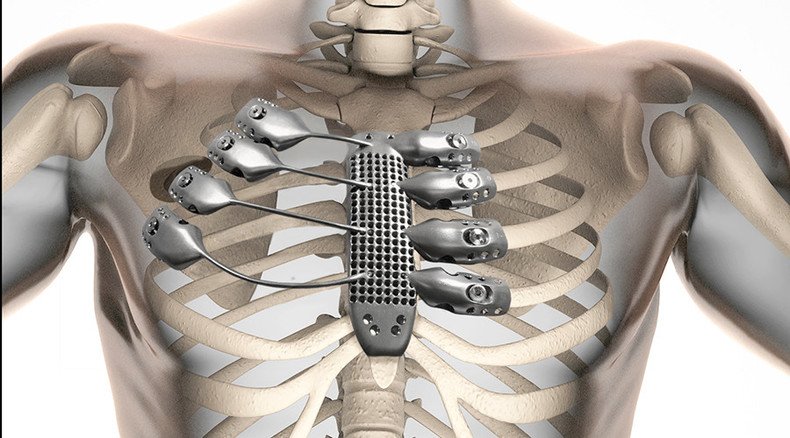

Patient gets 3D-printed metal ribs for the first time ever

In the world’s first operation of such kind, a cancer suffering patient was successfully implanted with a 3D printed titanium sternum and rib implant.

The implant was done for a Spanish patient, 54, diagnosed with a chest wall sarcoma (a form of cancer in which a tumor grows inside or around the rib cage). He needed a part of his rib cage including a sternum to be removed.

There was a risk that a traditionally manufactured implant could potentially come loose over time, increasing the risk of complications and re-operations, so the man’s surgeons decided to turn to 3D printing.

The technology allows for the creation of an implant that accurately replicates the size and form of the patient’ rib cage.

In order to bring their idea to life, the surgeons contacted Australian medical device company Anatomics. The Spanish team also made a high-resolution computer tomography scan to plan the surgery in details as to allow Anatomics to create an accurate implant that would match the removed part.

The details of the joint Spanish-Australian project initiated by Spanish surgeons were disclosed in a press-release by the office of the Australian science and industry minister, Ian Macfarlane, on Friday.

Rare ‘stone man’ disease could be treated, breakthrough research shows http://t.co/gslPHo0BOjpic.twitter.com/Lurf1tiytH

— RT (@RT_com) September 6, 2015"We thought, maybe we could create a new type of implant that we could fully customize to replicate the intricate structures of the sternum and ribs," said Dr. Jose Aranda from the surgical team at the Salamanca University Hospital in Spain that carried out the operation.

"We wanted to provide a safer option for our patient, and improve their recovery post-surgery," he added, as quoted in the press release.

"We wanted to 3D print the implant from titanium because of [the sternum and ribcage's] complex geometry and design," said Anatomics CEO Andrew Batty.

"While titanium implants have previously been used in chest surgery, designs have not considered the issues surrounding long term fixation," he added.

Altered blood cells hunt and kill cancer, lead to remission in some patients – report http://t.co/n2LFvmpCF2pic.twitter.com/AhYUIFZT1n

— RT (@RT_com) September 3, 2015Anatomics later created the implant in cooperation with Australian state-owned Commonwealth Scientific and Industrial Research Organization (CSIRO) using its powerful facility, Lab 22 that prints in metal.

"We built the implant using our $1.3 million Arcam printer," Alex Kingsbury from CSIRO's manufacturing team said adding that his organization would further cooperate with small and medium businesses allowing them to use expensive 3D-printing equipment they cannot afford otherwise.

"The printer works by directing an electron beam at a bed of titanium powder in order to melt it. This process is then repeated, building the product up layer-by-layer until you have a complete implant," Alex Kingsbury added.

‘Reprogramming’ cancer cells can reverse tumor – study http://t.co/PAh4HHD7aSpic.twitter.com/STrhbVwOBB

— RT America (@RT_America) August 25, 2015The implant was then transferred to Spain to be used in the operation. The Spanish surgeons had previously revealed their vision of titanium-printed implants in a theoretical paper published in the European Journal of Cardio-Thoracic Surgery.

"The operation was very successful. Thanks to 3D printing technology and a unique resection template, we were able to create a body part that was fully customised and fitted like a glove," Dr. Jose Aranda said.

12 days after the operation the patient was discharged from the hospital and was said to be recovering well.