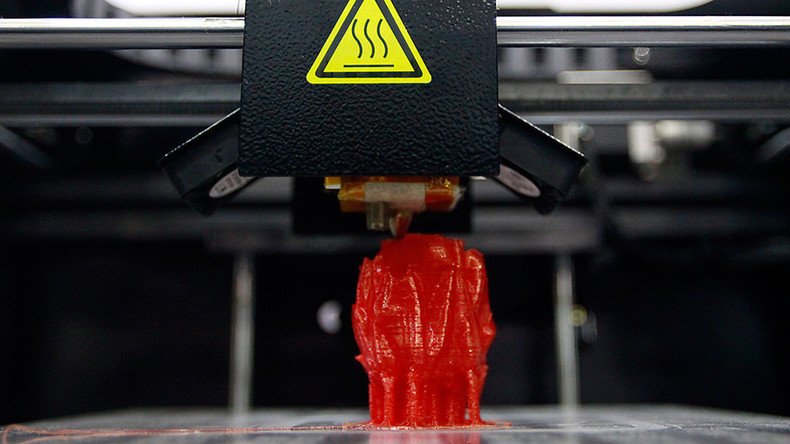

3D metal printer that works in zero gravity developed by British scientists

British scientist have designed a 3D metal printer that can function in zero gravity, allowing astronauts to easily produce vital spare parts while on space missions far from Earth.

The prototype has even been tested on the European Space Agency’s ‘vomit comet’ – a device used to simulate the weightlessness of space.

While 3D printers are an increasingly popular product, this new version is specifically designed to print metal in order to create key components for spacecraft.

“It’s challenging, metals are a different ball game,” the University of Birmingham’s Dr Luke Carter told the Times.

The device has been designed to run on a low wattage because in space “there are quite strict power requirements. It runs on 1,300w, less than a kettle.”

Weightlessness brings its own issues, because “most [printers] use metal powder. You don’t want that floating around.”

“It starts to sound a bit sci-fi,” Carter said. “We are targeting long-term space missions. Trips to Mars, a moon base. When we went to the moon in the 60s and 70s we could take everything we needed. It was a camping trip. If you are going to Mars, it is an 18-month journey.”

He pointed out that on such a long trip something relatively minor could ruin an entire mission.

“You get to the point where you are floating around in the pod, someone opens a cupboard and the hinge snaps. Then you have it flapping around the whole journey,” he said.

Carter said there was huge interest in the idea of 3D printing in space.

“Imagine how many components you would have to bring otherwise. Taking up a reel of aluminium wire is far better than an entire store cupboard.”

After testing the next step is to take the prototype to the International Space Station (ISS) for its first full space audition, Carter said.