Bone in the USA: Researchers 3D print potential replacement skeleton parts

Bones made out calcium could be going the way of the flip phone! Not really, but researchers at Northwestern University have developed a breakthrough “hyperelastic bone” that could be used in living tissue to bind bone and tendons together.

If this new composite bone is approved for humans, it could be used to treat several injuries. The hyperelastic bone can not only function as a custom bone implant but can also promote bone growth.

The current options for bone grafts range from ceramics to mineralized collagen. But the side effects from current bone grafts pretty much result in what can be expected from introducing a foreign object to the body: infections, pain and implant displacement. However, the hyperelastic bone could be a viable alternative with minimal side effects.

Pigs with lab-grown bone implants ‘doing great’https://t.co/PaEUcGTIJ9pic.twitter.com/cbrLStkdnd

— RT America (@RT_America) June 23, 2016

The first test of the hyperelastic bone was promising. They began with a mouse and surrounded two of its vertebrae with the porous synthetic bone. Eight weeks later, they discovered that bone and tissue had grown into graft material and fused the vertebrae together.

Their next trial was on a Rhesus macaque with a skull injury. The damaged part of the skull was removed and replaced with the graft material. Four weeks later, the graft responded by growing into the existing bone material and was integrated with the skull.

The researchers behind the graft material weren’t just aiming for successful transplants.

The parameters for their project required that they develop an alternative graft that was cheaper, easy to implant during operations and customizable to be used by a wide range of people.

It’s too early to know whether costs related to potential procedures using these grafts will be lower than existing options. However, the use of 3D printing does offer a faster and more customizable graft for patients. In addition, its flexible properties allow surgeons to manipulate the bone more than current options.

Scientists may have ‘game changer’ drug to treat Alzheimer’shttps://t.co/3Cjygw983Cpic.twitter.com/YoP3GDEh12

— RT America (@RT_America) September 1, 2016

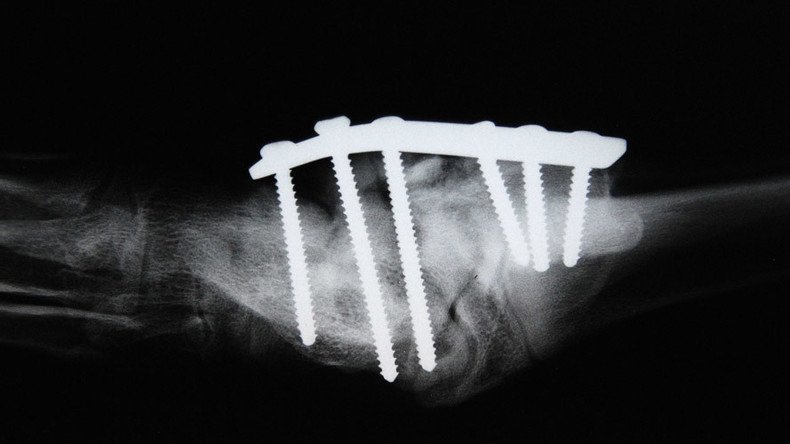

In addition, because the material is less likely to be rejected by its host, it could also be used to coat other methods of treating injured bones – such as screws and pins.

While the hyperelastic bone has yet to be tested on humans, it is already showing promise. In fact, researchers grew human stem cells on the graft in the lab.